While they may be small in size, wedge gaskets are a big thing! It helps to prevent leaks in pipes or machines which can, of course be quite large problem. Below are the types of wedge gaskets which you will come to know after reading this. They can be found in all sorts of shapes and sizes, but the most popular style is a triangle. Hence they are called as wedge gaskets!

Benefits of Wedge Gaskets The primary purpose is their ability to prevent liquids and gases from escaping, which is critical. Leaks can be harmful to the people working around them, and leaks will cause machines to wear out sooner. Machines break down more easily when they begin to leak. They play a part in reducing leakages and vibrations to effectively keep the machine working better and for a longer time. This can save businesses lots of money, they won't be fixing things up as often so all that extra cash could go on to more useful areas.

These gaskets are used in various fields and industries. For example, they are in cars, and planes and oil & gas; as well as food & beverages. For cars, wedge gaskets are indispensable in engines and exhaust systems to help maintain a stable flow. What do airplanes need them in their engines and fuel systems so that everything stays safe, efficient? Pipelines and valves in the oil and gas industry need wedge gaskets to avoid potentially dangerous leakage. For food and drink, they assist in machines that keep products processing through them securely to preserve freshness/integrity.

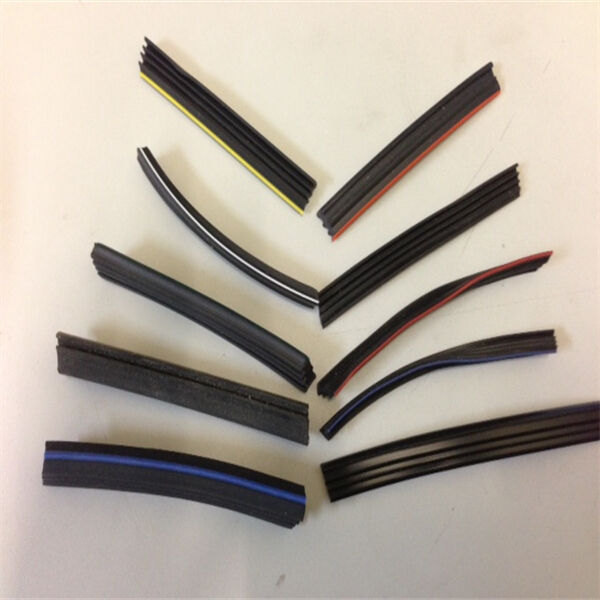

There are several things that you need to consider with a wedge gasket when you are making your choice. You also need to think about materials, the project size and form factors required. Materials react to heat and chemicals differently so its important to make sure you have the right material for what you need. Even its size and shape should match the machine pipe properly. This is so it gets the chance to work well and perform without any issues.

Wedge gaskets seal between two surfaces to prevent leaks. If inserted between two pieces, they will fill any small flaws or openings to complete a gapless connection providing perfect sealing and guarding from leaks. The wedge profile of the gasket reduces pressure points on the cover/flies, which helps distribute stress more evenly across this surface area. It thus improves the efficient functioning of the seal. In addition, the wedge gaskets are also reusable. They are not only cost effective, but also an intelligent solution for many needs!

Our certification under the ISO9001/SGS wedge gaskets assures our commitment to superior customer service and continual improvement Our products are exported to European and American markets meeting stringent international requirements

we offer wedge gaskets service and an extensive after-sales assistance which includes no-risk refunds or replacements in the event of any product-related issues this is a way to build trust with customers and ensures their satisfaction these attributes help us maintain our status as a leading company in the field of rubber and help us continue to grow

Our modern molding capabilities allow us to develop high-quality and precise rubber products that are highly wedge gaskets and customized. We employ sophisticated design tools to turn customer ideas into products that satisfy the strict specifications of various sectors, such as medical, electronics, automotive and more.

We have wedge gaskets than 35 years of experience within the rubber industry. We have an impressive amount of technical know-how. This enables us to comprehend the requirements of customers in depth and to maintain the highest standards throughout the production process.