A gasket is a very important component of the machines, where it employed in several industries. They are essential for preventing gas or liquid leaks from the machines. A particulate named NBR gasket is commonly used as well. Followed by the acronym NBR, which stands for nitrile butadiene rubber. Such a gasket is particularly suitable in factories and other work environments where floor to ceiling vision can be vital. In this blog we will learn more about NBR gaskets and why they are good for sealing.

In fact, NBR gaskets are one of the most used kinds in so many fields like: automotive industry construction food production medicinal. They are so popular mainly because they resist oil, fuel and many other chemicals extremely well. That way, it is easy to get the machines functioning correctly without having any leaks. Furthermore, NBR gaskets could perform in both hot and cold temperatures. This allows them to be used in many different environments. They are heat resistant and can work in the temperatures from -40°C to 120°C this makes them an ideal choice for use where conditions vary significantly.

A gasket made of NBR offers a nearly perfect seal that does not let any liquid fuel, oil or gas go through. The reason they can do this is due to the nature of thier usefull properties, stretch and compress! NBR gaskets are an excellent way to create a strong enough seal because, being used together with the adhesive and sealing effect of Nitrile material can actually push itself into any small gaps between two surfaces for pressurized systems. The importance of this powerful seal cannot be understated as it helps machines and equipment to stay dry without leaks. Leaks can damage machines, and the ones who are using them will face risk of their safety if there is a leakage. Companies can protect their equipment, as well helping prevent staff injuries by using NBR gaskets.

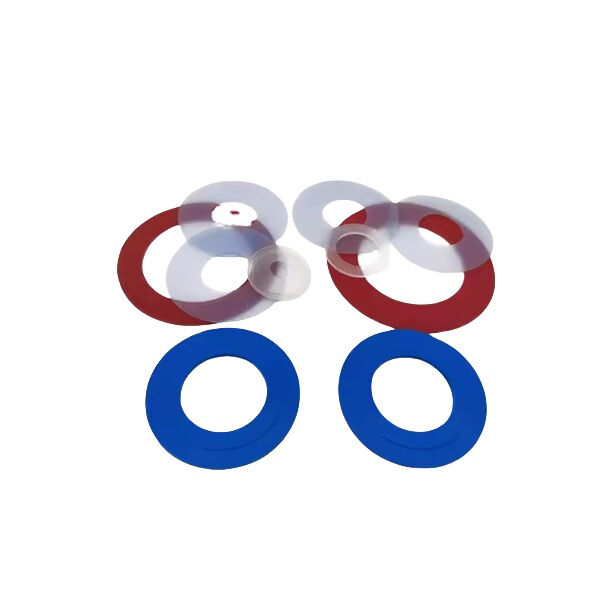

Any time you require a gasket for any type of equipment, NBR rubber gaskets are an excellent decision. Because they are easy to install, it is possible for workers complete that part of the process fast. They are also Unconstrained in Essential Industries which means that they can be used across all the industries. NBR gaskets are available in a wide range of place and contour, this means that they can fit into the requirements for specific devices together with machines. This flexibility is a huge benefit as it helps guarantee that you can locate the best gasket for pretty much every application.

NBR gaskets are reputedly long lasting and have a low chance of leaking over the years. These workhorses of leather are also highly robust and long-lasting, which ensures your money is well spent with little need for frequent replacements. This is key because it lowers the number of replacements needing to be made, which saves businesses time and money. Hence, industries that need a non-leaking equipment and machinery should invest in the good NBR gaskets only. These industries are now using NBR gaskets to run their operations smoothly and securely.

Our sophisticated nbr gaskets capabilities allow us to design and manufacture precisely-crafted and custom rubber products. We employ sophisticated design tools to transform the ideas of our customers into products that meet precise specifications in various industries, including electronic, automotive, medical and more.

We have been certified by the nbr gaskets and ISO9001 international quality management system ensuring our commitment to top quality and continuous improvement in order to satisfy the requirements of our customers Our products are exported into European and American markets They meet stringent international standards

we offer personalised service a robust after-sales support and unconditional refunds or product replacements in case of any problem with the product this commitment nbr gaskets customer trust and ensures their satisfaction these attributes contribute to our reputation as a respected supplier of rubber products industry which supports our steady expansion and development

nbr gaskets have more than 35 years of experience in the rubber industry. We have a wealth of technical expertise. This allows us to fully comprehend customer needs thoroughly and maintain the highest standards throughout the production process.