Importance of Rubber Seals in Industrial Applications

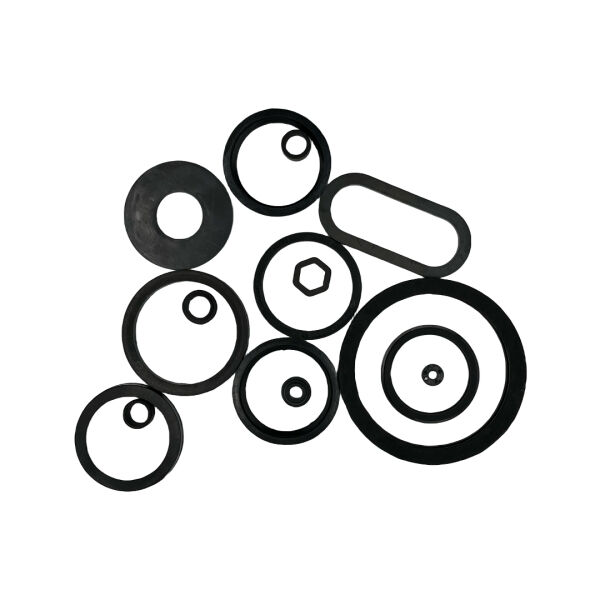

We depend on machinery and equipment daily to function properly, but these are widely dependent on rubber seals for smooth operation. PULI Rubber Seals serve as protectors of structures, not allowing for leaks and keeping them air tight. Because they are so versatile and come in such a wide variety of shapes, sizes it is important to choose the right specific for your application.

Rubber seals are now an important part of machinery in today's industrial world, for liquid transport such as gases hardware. Incorrect seals may cause the device to malfunction, damage equipment or lead to environmental disasters. The medical device sector rests heavily on PULI ring rubber ring for maintaining clean conditions and avoid contamination.

Choosing the right rubber seal is very important. Others focus on sealing in contamination and give a good seal. This part is created in such a way that it will keep your equipment safe with no leaks and protection for your stuff! The compatibility of the rubber gasket with substances they are in contact with should be considered because hostile reactions can damage machinery.

Industrial rubber seals are particularly robust and resistant to the most extreme of conditions. By doing this, it can not only help the machines run efficiently but also become a cost-efficient method in terms of reducing breakdowns and replacements. Rubber seals like PULI Rubber O Ring and gaskets perform different functions in machines, which helps to make them operate smoothly.

The regular maintenance of rubber seals is fundamentally important in extending the service life of machinery. Dirt and debris buildup places the Rubber Stopper at risk, leaks will occur. It is important to perform regular maintenance such as lubrication, replacement of worn seals in time.

The rubber seals are very important things in machinery and industrial applications. Significantly prolonging the service life of any machine and minimizing failures depends on careful choice as well as quality maintenance in operation.

rubber seals are able to design and manufacture custom extremely precise rubber products using our cutting-edge molding capabilities. We make use of advanced design techniques and tools to transform customer concepts into products that meet exact specifications in a variety of industries, including automotive, electronics, medical and many others.

Our certification under the ISO9001/SGS international quality management system ensures our commitment to top customer service and rubber seals Our products are sold on European as well as American markets They comply with strict international standards

With over 35 years of rubber product manufacturing we have deep expertise in the industry and rubber seals. We fully know the needs of our customers and maintain high-quality standards throughout the production process.

we offer personalized customer service as well as robust after-sales support including full refunds or replacements on any issue with our products this ethos builds customer trust and ensures their satisfaction these rubber seals help us maintain our standing as a pioneer in the field of rubber and support our continued growth