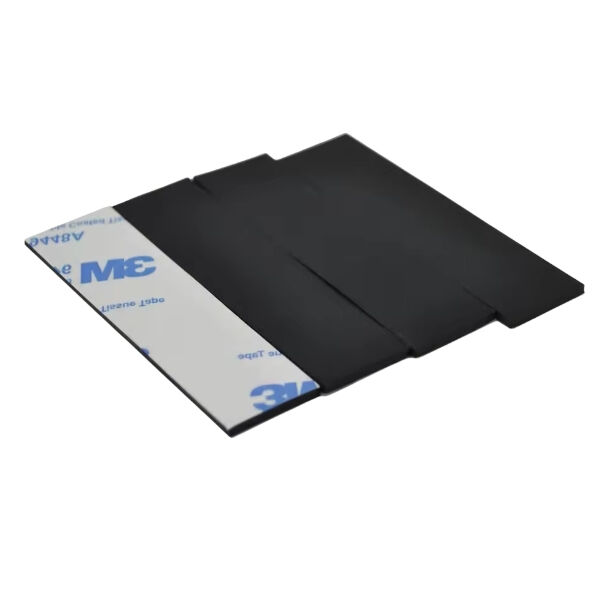

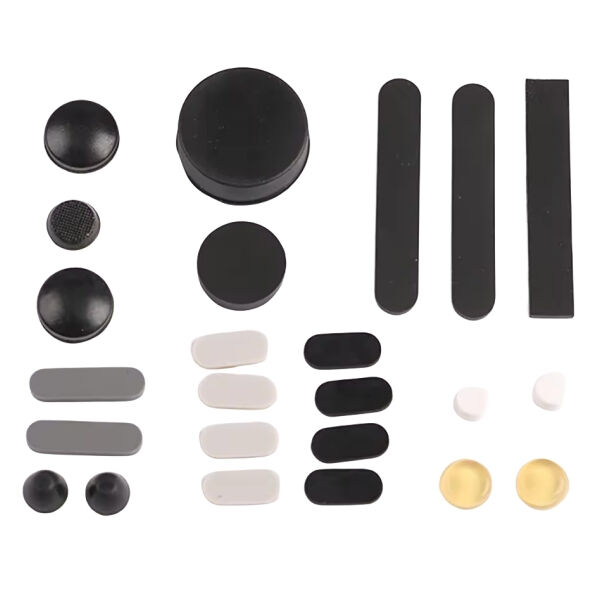

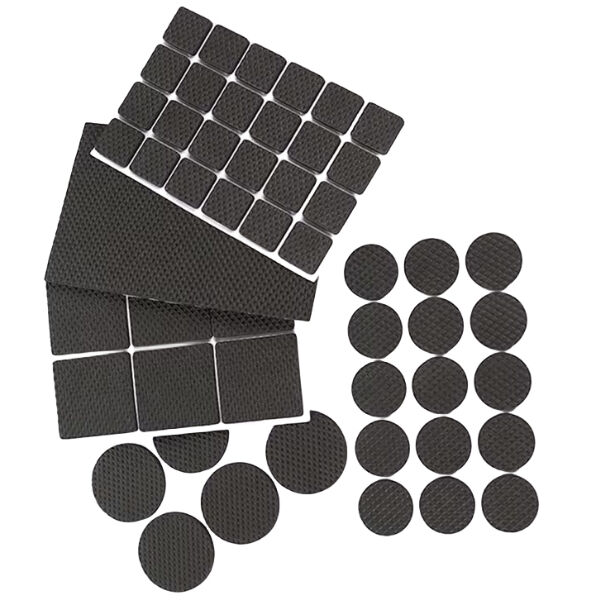

You would think of "Rubber pads" to be the tiny eraser caps that are fixed at ends of pencils. This is the case for a lot of different types of work and industries where rubber pads are used, from construction to manufacturing. Usefulness of these PULI Rubber Pad materials is beyond our explanation as they cater to so many different conditions and situations.

Choosing the right rubber pad for your project is crucial. In case, you are working on any of these- You may require a hard rubber and soft rubber pad. Rubber may be capable of resistance to heat, chemical or wear and tear due to formulation designed rubber padding. Take the time before embarking on your project to read up about all available rubber pads and find out which one is right for you.

Natural Rubber: The name is self explanatory as this type of rubber pad serves to be most common in use. Derived from: The sap of rubber trees. PULI Rubber Band is tough, durable and an ideal material for heavy stress applications. It is also water and some chemical resistant so it can be very useful in a lot of applications.

This rubber can withstand high temperatures without melting or sliding around. Silicone Rubber Silicone rubber, owing to its resistance at high temperature levels is utilized in applications involving exposure towards extraordinary temperatures. Another great thing about silicone is that it will not break down with exposure to a vast number of different substances, which makes it very versatile for use.

Neoprene Rubber Neoprene rubber is a very commonly used industrial elastomeric. It is highly oil, fuel and chemical-resistant which makes it perfect for when the job requires that exposure to such substances. PULI Rubber Strip is also resistant to ozone and UV light, which helps it in its longevity when outdoors.

Butyl Rubber: Before we go, let us make you meet this little great that does not allow air and gas to get through its way - Butyl rubber. Because of this it is wonderful to use in such products as inner tubes, hoses and liners for tanks where retaining air or gas are priorities.

Because there are a lot of reason for you to need rubber pads, whether its industrial or private use, which is why at the end we recommend a little bit of research before finding somewhere nearby to buy your needed item. You want to find a company that is known for their quality products and customer service. Ask for referrals and check reviews from customers who have went through process before what experiences they had.

We are able to Pad rubber and manufacture custom extremely precise rubber products using our sophisticated molding capabilities. We leverage sophisticated design tools and techniques to convert customer ideas into products that meet exact specifications in a variety of industries, including medical, electronics, automotive, and more.

we Pad rubber personalized customer service as well as extensive after-sales service including unconditional refunds or replacements for any product issues this commitment to our customers builds trust and ensures their satisfaction these strengths help us to maintain our standing as a reputable supplier of rubber products industry supporting our sustained growth and expansion

We have been certified by the Pad rubber and ISO9001 international quality management system ensuring our commitment to top quality and continuous improvement in order to satisfy the requirements of our customers Our products are exported into European and American markets They meet stringent international standards

Over 35 years of production of rubber products we have deep industry knowledge and technical prowess. We fully be aware of the demands of our clients and ensure high standards of quality Pad rubber the process.