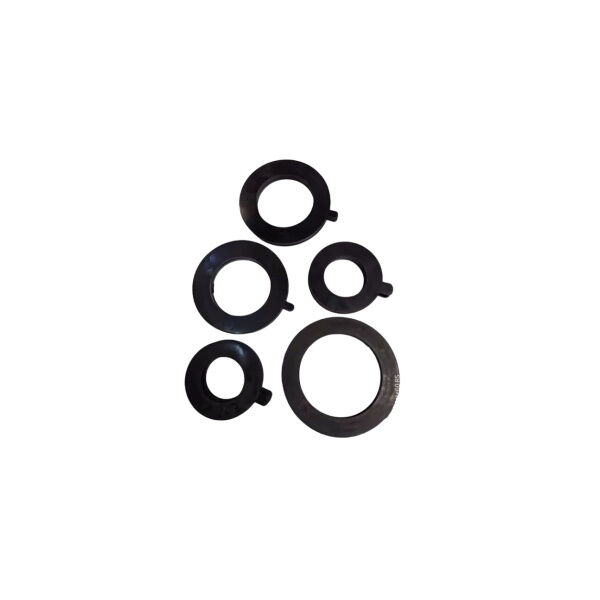

Round rubber flanges with a hole in the center. Types of magnets, their shapes and sizes are diverse as well which means that they can be used in various ways for us on everyday basis. In this post, we will go through where rubber flanges are used and how they manage to retain liquids & gases inside without leaking out; what makes them a great choice for multiple applications? What are the benefits of using these in business, and how it is being designed to perform effectively.

They are used in numerous places and industries, but what exactly is a rubber flange. In cars, for instance, they are used to join the tubes and hose that provide essential liquids such as fuel or oil. In the case of hospitals, rubber flanges are used to connect together machines that transfer a host of liquids and gases integral for treating illnesses. For example, rubber flanges are used by builders and construction workers to attach one part of a building to the other so that everything fits together seamlessly. Rubber flanges can even be observed in restaurants to join the food and drink maim pipes. Rubber flanges have to perform in a range of applications.PictureBoxSizeMode

(2) Rubber flanges are made to seal off liquids and gases from escaping into the atmosphere. They are round with a raised edge that seals when clamped over the center hole. Where no liquid or fuse escapes, this seal is a very important one. The rubber flanges themselves are highly durable, able to withstand extreme pressure and heat. They are able to withstand the elements which make them ideal for high duty environments such as oil and gas.

Rubber Flanges — With rubber flanges, it is more about choosing the right type for your particular needs. Rubber flanges are made according to the job and application. Rubber flange — Depending on the size and shape of your pipes or hoses. You will also want to think about the liquid or gas that you need it for and how hot/cold, high/low pressure it has to survive. You should likewise look out for a rubber flange that is of the best quality as this will have to work in challenging conditions, so you want it ti last!

Rubber Flanges with Business and Industries Advantages: quick and easy of installation (time saving) can be used in various environments making them flexible Flanges are of resilient material to work at extreme temperatures. They are also non-rusting and corrosion resistant, ideal for the oil & gas industries where exposure to their elements is commonplace. Furthermore, rubber flanges need to be maintained almost not anything and this makes them last longer which in turn maximizes the operational efficacy of businesses as downtime is reduced.

The rubber flanges is especially designed to fit tight on the hole in middle. This is important because the seal stops any liquid or gas from leaking out through it. The beading of the flange increases pressure, allowing a lasting seal. Rubber flanges are made out of a range of materials like natural latex, synthetic rubber and also silicone. The material selection is determined by the application at hand and where that flange will be present.

we offer personalized service and an extensive after-sales assistance which includes unconditional refunds or rubber flange for any product issues this ethos builds customer trust and satisfaction these attributes contribute to our position as a respected player in the rubber products industry which supports our steady expansion and development

Our sophisticated rubber flange capabilities allow us to design and manufacture precisely-crafted and custom rubber products. We employ sophisticated design tools to transform the ideas of our customers into products that meet precise specifications in various industries, including electronic, automotive, medical and more.

We have more than 35 years of experience within the rubber industry, and have an impressive amount of technical know-how. This enables us to rubber flange the requirements of our customers thoroughly and maintain high standards throughout production.

Our certification rubber flange the SGS/ISO9001 international quality management systems assures our commitment to top customer service and continuous improvement Our products are exported into European and American markets They are in compliance with stringent international standards