So what happens when the surface you need to seal is anything but a conventional size or shape? This is where you can find salvation without losing another arm or a leg: custom rubber gaskets. Custom rubber gaskets are unique to your specific and individual sealing requirements. They are versatile in size, shape and material which can be applied to many situations This adaptability makes them precious for individuals, or even associations that are searching for particular answers.

Poor gaskets not read temp really well, you can't use them in such very hot or cold temperatures which are applied to industries. These have the capability to resist chemicals, oil and other liquids and create a durable seal. This durability is important in a lot of industries were, machinery has to operate under extreme conditions.

Rubber gaskets that are customized (and not more) for industries They are also an extremely functional tool in the construction, automotive and various other sectors. Construction machines for example need custom gaskets to seal pipes and containers in a proper way. The gaskets are a necessary element of ensuring the entire system actually stays heldup, and that is crucial for safety at construction sites.

The process of making custom gaskets is predominantly used in the automotive industry where car mechanics depend on them to ensure their engines and transmissions continue running smoothly. If these gaskets fail, it could spell doom for your vehicle. Even home appliances such as refrigerators and ovens have custom rubber gaskets. It seals the doors or windows of a house, and serves to safeguard everything inside.

With custom rubber gaskets, quality is indeed a top priority. If the gasket is poorly put together then that can lead to leaks and particularly in this case, quite expensive repairs. This is one of the main reasons it will become valuable to choose manufacturer using top quality materials and precision manufacturing. Better performance and a longer life span means you will spend less money on gaskets for years to come.

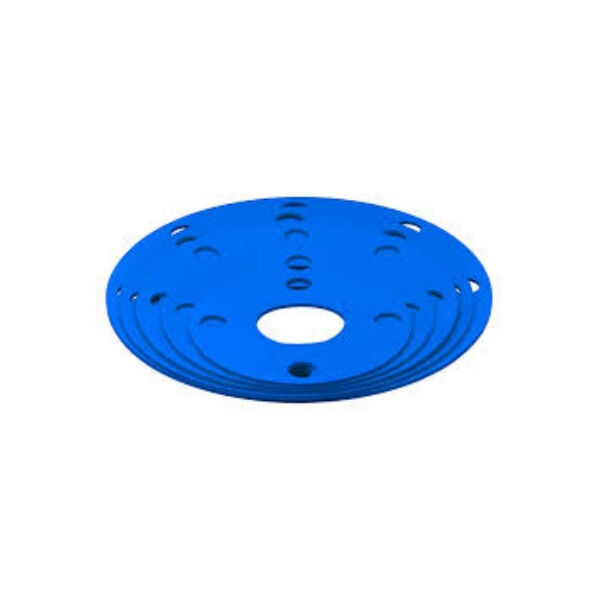

Rubber gaskets can also be fabricated from any number of materials including; Silicone, Neoprene®, EPDM and Viton®. Each of these materials has unique characteristics, so it is vital to choose the suitable material for your purpose. A high quality manufacturer will be able to guide you on what material would work best for your specific project and helps provide the right gasket that is perfect fit based on your unique specification.

There are several key steps in the process of making your own custom rubber gaskets. The process begins by the manufacturer working closely with you to determine precise dimensions and information required for your gasket. You can do this by showing them a sample of the surface you want to seal, or provide accurate drawings illustrating your expectations.

Over custom rubber gaskets years of production of rubber products We have deep understanding of the industry as well as technical expertise. This enables us to comprehend the requirements of customers in depth and to maintain the highest standards throughout the production process.

We are certified by the SGS and ISO9001 international quality management system ensuring our commitment to high-quality products and constant improvement to be in line with the expectations of customers Our products are custom rubber gaskets to European and American markets meeting stringent international requirements

Our sophisticated custom rubber gaskets capabilities allow us to design and manufacture precisely-crafted and custom rubber products. We employ sophisticated design tools to transform the ideas of our customers into products that meet precise specifications in various industries, including electronic, automotive, medical and more.

we offer personalised service and custom rubber gaskets after-sales service including full refunds or replacements on any issue with our products this commitment builds customer trust and ensures their satisfaction this helps us to maintain our reputation as a leader in the field of rubber and help us continue to grow